Single source rainscreen façade manufacturing can offer a multitude of potential and demonstrable benefits, helping to realise architectural designs and playing a pivotal role in the successful delivery of diverse yet complementary facades.

Multi-sourcing rainscreen façade manufacture may be perceived as benefitting from increased flexibility and capacity, combined with reduced risk and dependency. However, a multi-source strategy can complicate supplier relationships and require greater resources to manage them. Information sharing may become more complex, costs may be higher, and challenges may arise in terms of quality control and efficacy. Specific to costs, lower order volumes will reduce bargaining power and lessen efficiencies gained through economies of scale.

The advantages of single source rainscreen façade manufacturing can include the fostering of a much stronger, longer-term relationship with one supplier. This results in a partnership approach that can build trust, transparency, and shared benefits. It can also see lower costs due to economies of scale. Crucially, the integration of different systems is seamless if they are designed, engineered, and manufactured by a single source.

That said, the key to successful single source rainscreen façade supply is choosing the right partner. A well-established company with a proven track record of manufacturing a wide range of rainscreen systems; that is what provides the reliability to combat any concerns about risk. A manufacturer with agile design and manufacturing capabilities can provide the flexibility and capacity required of even the largest projects. And the availability of systems that are fully tested provides confidence in cladding.

Bailey’s core value is Stronger Together, and it is through partnering with architects and contractors that we see our customers and specifiers grow and prosper.

The company has been operating in the construction industry since 1975 and boasts a range of rainscreen systems that includes sleek hidden-fixing cassettes, expanded mesh, timber-effect planks and a host of other metal systems that offer options to suit any application. The availability of materials and finishes from Bailey also empowers the architect to realise their design, with the capability to manufacture using a range of natural metals, in-house powder coating facilities and anodizing options for aluminium.

From complex projects to one off designs, Bailey’s design team are a valuable resource, being able to collaborate from initial designs through to engineering, specifications, and warranty.

Proven rainscreen systems from Bailey are tested to CWCT, BS8414, BR135 and EN13501-1, providing peace of mind and confidence in cladding. Manufacturing is certified to ISO9001 and ISO14001 Quality and Environmental Management Systems. And Bailey partners with the NBS Source and NBS Chorus specification authoring service.

A project that exemplifies the success of single source rainscreen manufacture is Elwick Place, a striking leisure and restaurant development located right in the heart of Ashford Town Centre, one of the fastest growing towns in the Southeast.

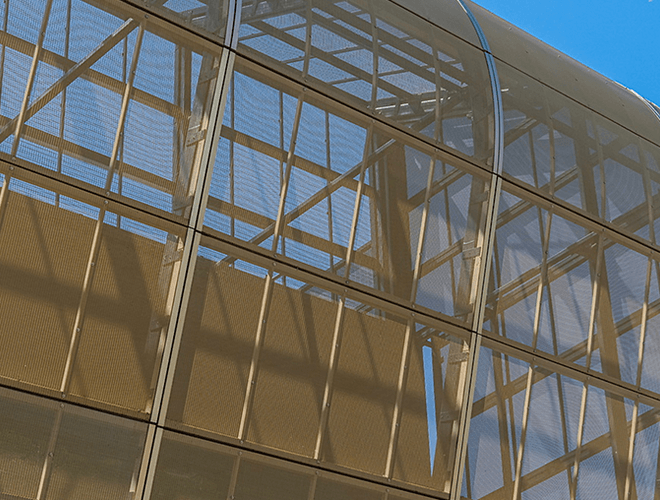

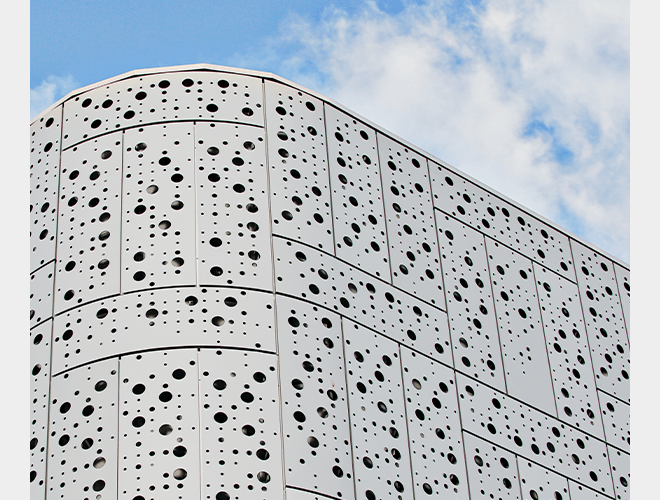

Bailey tested, developed, and manufactured a custom rainscreen cladding design for a new-build hotel and cinema at Elwick Place. A successful collaboration with Guy Hollaway Architects, and subcontractor Prater helped bring this stunning building to life.

Effortlessly Phenomenal is the goal of Elwick Place. The stunning, intricate, and beautiful design needed to be delivered within stringent architectural constraints. Bailey worked in a cooperative partnership to supply high-quality systems on time and within budget.

The single-source approach to rainscreen manufacture added considerable overall value to the project and was instrumental in delivering superb results. The facades consisted of a range of cassette panels in bronze and black, expanded mesh cladding and perforated panels, all in various shapes and sizes, with integrated curves and bespoke roof and wall interfacing. Products were delivered to site with practical, high-quality packaging and meticulous transport logistics, cementing the strong partnership between manufacturer, specialist contractor and architect.

Project Architect Mike Pearson said of Bailey, "I knew I could pick up the phone and speak to the team at Bailey, and that any issues would be resolved. The people of Ashford love Elwick Place, it's received an amazing response".

Related Work & Articles