Author

Bailey

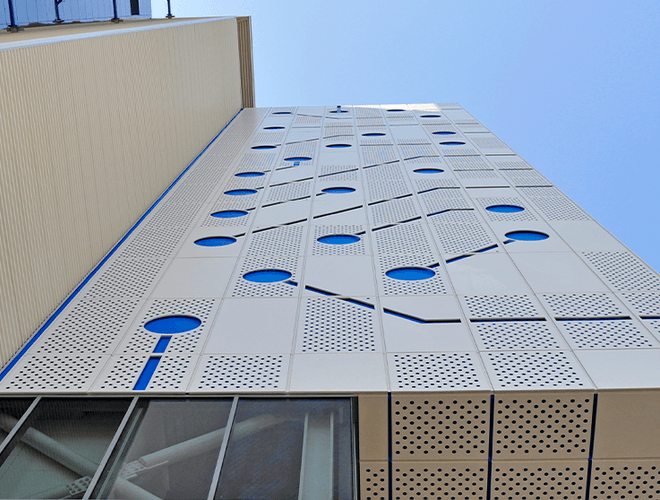

CWCT (Centre for Window & Cladding Technology) use various testing methods, which determine the level of serviceability of a window, façade or cladding systems when subjected to various levels of water, air and solid object impact. The final level of certifications depends on the pressure reached or the degree of damage caused after impact.

The standards that make up the CWCT tests are calculated to give independent verification that windows and cladding designed for the building envelope, will achieve the values expected. Façade failure is the most common cause of failure in a new building (source: Centre for Window and Cladding Technology). CWCT testing, combined with good design and installation, will give ultimate peace-of-mind that a product will deliver the performance it’s intended. The tests include:

- Test pressure requirements based on design and wind load

- Exfiltration Air leakage

- Impact

- Suction

Test 1 – Dynamic Test

This consists of spraying water at the wall continuously for 15 minutes with the use of an aircraft engine to provide the direct wind force. This test is purely to measure the amount of water that penetrates the rain-screen system. It is for information only and not a Pass/Fail test – unless of course, the panels dislodge from the wall.

On completion of this test, the entire sample wall must be fully dried, any fuel/oil from the engine cleaned off and all joints sealed. A set of test probes are then set up to read all deflection in the panels at various positions.

Test 2 – Suction & Pressure Test

This consists of connecting a fan to provide a vacuum and the pressure into the void between the panels and the wall. Firstly the vacuum simulates the panels being pushed against the wall by an external force, increasing in stages until the safety factor is reached. Secondly, the pressure is added to simulate the panels being ‘sucked’ away from the wall. Again, this increases in stages until the safety factor is reached.

If at any time, the sealing of panel joints fails, additional sealing must be applied.

On completion of this test, the test probes and sealing tape are removed in the positions where impact testing is required.

Test 3 – Impact Test

This consists of a series of impacts using a steel ball and then a 50kg leather bag of glass beads on a pendulum. Full sets of impacts are carried out, photographing all results. Once complete, safety impact tests are carried out at each position whilst being videoed.

In line with its commitment to quality and performance, Bailey has submitted relevant façade and building envelope products for testing. Products now tested to CWCT standards include:

Platinum Rainscreen types:

- Linear (cassette panels with joint straps)

- Modular (Cassette panels with folded ends)

- Fusion (1.5mm aluminium cassette panels with a honeycombed aluminium backing pressure-bonded to the rear of each panel)

Vee-Plank Rainscreen

102mm I-Line system with 300mm web.